Key Functions of an Auto Rehanger

- Automatic Transfer:

- Transfers poultry carcasses from one processing line to another without manual intervention.

- Ensures seamless transition between different stages of processing, such as from defeathering to evisceration lines.

- Workflow Continuity:

- Maintains continuous and efficient movement of carcasses through the processing plant.

- Reduces bottlenecks and delays by automating the rehanging process.

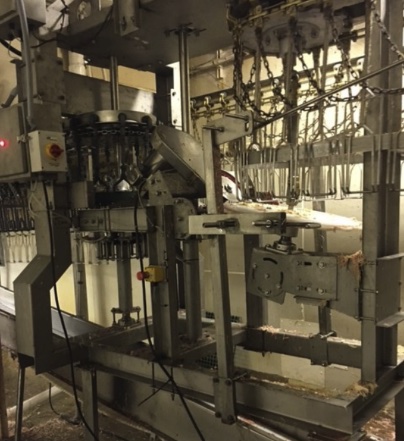

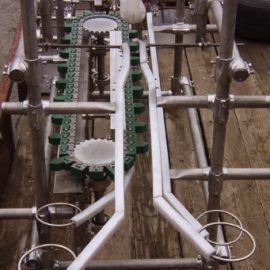

Components of an Auto Rehanger

- Gripping Mechanism:

- Equipped with automated arms or hooks that securely grip the poultry carcasses.

- Designed to handle carcasses gently to avoid damage.

- Transfer System:

- Moves the gripping mechanism from the end of one line to the start of another.

- Can include overhead tracks, conveyors, or robotic arms, depending on the specific design.

- Control System:

- Synchronizes the movement of the rehanger with the speed and timing of the processing lines.

- Uses sensors to detect the position of carcasses and ensure precise and accurate transfer.

Advantages

- Efficiency:

- Automates a labor-intensive task, increasing the speed and efficiency of the processing line.

- Reduces the need for manual labor, freeing up workers for other tasks and reducing labor costs.

- Consistency and Reliability:

- Ensures consistent and accurate transfer of carcasses, minimizing the risk of human error.

- Provides reliable operation, maintaining the smooth flow of processing.

- Hygiene and Safety:

- Reduces the risk of contamination by minimizing human contact with the carcasses.

- Enhances workplace safety by automating the rehanging process.

Application

- Poultry Processing:

- Used in poultry processing plants to transfer carcasses from one stage of processing to another.

- Essential for maintaining the efficiency and continuity of processing lines, particularly in high-volume operations.