Key Functions of an Inline Bird Unloader

- Transfer from Transport Modules:

- Transfers poultry from transportation crates or modules onto the processing line.

- Ensures a smooth transition of birds onto the processing line without causing injury or stress.

- Automation:

- Automates the unloading process to reduce the need for manual labor and increase processing efficiency.

- Ensures a consistent and steady flow of birds onto the processing line, optimizing throughput.

Components of an Inline Bird Unloader

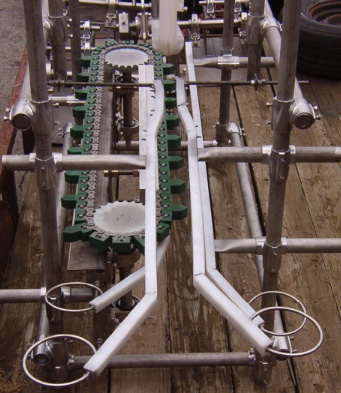

- Conveyor System:

- Transports poultry from the transportation modules to the processing line.

- Typically consists of belts or rollers that move birds along the unloading path.

- Unloading Mechanism:

- Includes mechanical or pneumatic devices such as gates, ramps, or lifting systems that transfer birds from the transportation modules onto the processing line.

- Designed to minimize stress and injury to the birds during the unloading process.

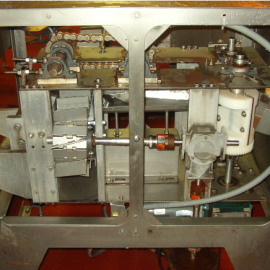

- Control System:

- Coordinates the operation of the unloading mechanism with other components of the processing line.

- Monitors input signals from sensors and ensures smooth and efficient unloading of birds onto the processing line.

Advantages

- Efficiency:

- Automates the unloading process, reducing the need for manual labor and increasing processing speed.

- Ensures a continuous flow of birds onto the processing line, optimizing throughput and minimizing downtime.

- Animal Welfare:

- Minimizes stress and injury to the birds during the unloading process, ensuring humane treatment and compliance with animal welfare standards.

- Hygiene:

- Helps maintain cleanliness and hygiene in the processing area by preventing cross-contamination between birds and transportation modules.

Application

- Poultry Processing:

- Used at the beginning of the processing line to transfer poultry from transportation crates or modules onto the processing line for further processing.